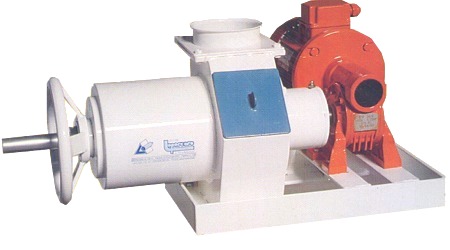

It is used to feed with the greatest precision the wheat so it can work both, as wheat feeder in pneumatic transport cleaning and in the first breaks, both as blender since it allows to associate different kind of wheat in perfectly controlled quantities.

A cup rotor turns at the inside of the machine which is equipped with a superior inlet and a lower outlet. The falling wheat fills the moving cups which then discharges it from the lower outlet. The bolt in the cups can run partially at their inside. By filling more or less the space you can reduce or rise the capacity and so the flow of wheat.The movement of the bolts is produced by means of a little steering-wheel. By tourning it the axial movement of the driving screw is produced. On this screw a graded scale is cut into in order to indicate the position of the bolts and so the degree of filling of the cups and the corresponding production per hour.