Besides the milling industry, the LF filter is used very well to recuperate lime dust, gypsum, calcium carbonate, mineral and vegetable carbon coke, phosphorite, animal mineral phosphate, bauxite, carborundum, abrasives, magnesium, manganese iron, metallic oxide, talc, tannin, pigment etc..

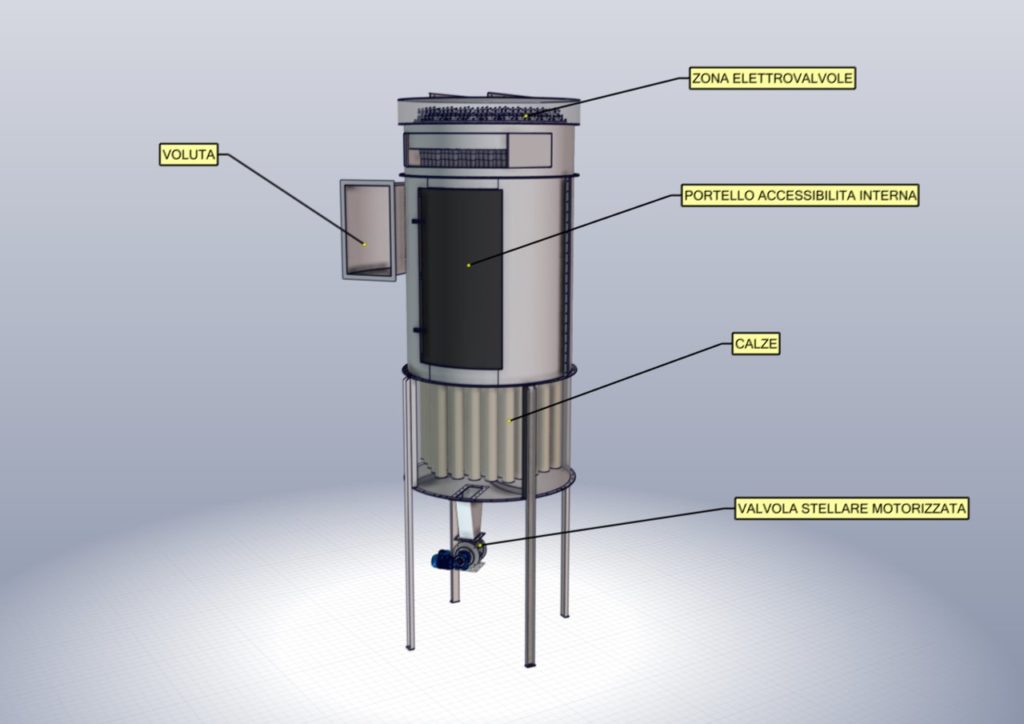

The dusty air arrives in the filter cylindrical body through the upper inlet. This is elliptical in order to make easier the decantation effect. Indeed, by slowing down the air velocity, the heavier part of dust falls in the descharging worm without passing through the filtering sleeves. The residual dust deposits on the sleeves and it is subsequently removed by a strong air shower, according to pre-determined cycles.

In the pipes the compressed air produces a depression which calls other air from the inside of the filter hat. The two fluxes produce an air current which moves very fast towards below. This current shakes violently the sleeves provoking the dust detachment which is then gathered in the discharging hopper. The purified air gets out from the superior part of filter.