It is a static machine designed to eliminate, by means of air, the lightest impurities such as seeds, withered grains, straws and so on with the utmost efficiency, minimum encumbrance, reduced assembling and working costs.

The cereal is evenly distributed over the entire length to be invested in against the current by the flow of air that removes all the lightest screenings. The settling chamber provides the separation of these screenings from the air so that it returns clean to the processing circuit.

The fractioning of the cereal and the screenings can be varied within wide limits thanks to the possibility of a precise and multiple air adjustment.

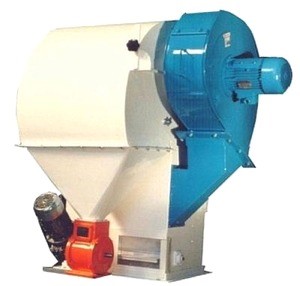

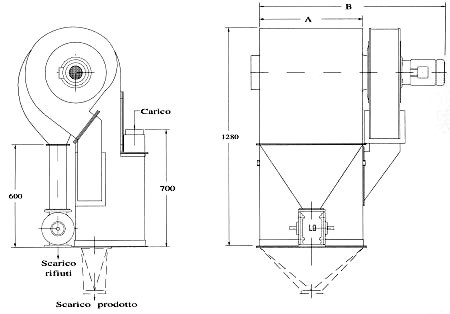

Its construction, completely, metallic and compact, consists of:

- On the front side a feed device which you can adjust;

- Support on floor. Rectangular housing with inspection doors. On the upper part there is a settling chamber which allows separation of light impurities inhaled by air.

- At the inside of the rectangular housing there is a vertical aspirating channel which lets the cereal falling freely and be run down by a strong ascension air current. You can adjust its velocity so as to obtain the utmost efficacy of separation. The channel is constructed with particular criterions which ensure the uniform distribution of fluid threads, avoiding, in this way, whirlwinds, dangerous loss of pressure and relapse of impurities